Steel scrap is a cornerstone of the steel industry, playing a crucial role in reducing CO2 emissions, conserving resources, and enhancing economic efficiency. However, each stage of scrap processing presents challenges that must be overcome by steelmakers. As governments worldwide push for net-zero commitments and stricter recycling regulations, the industry faces increasing pressure to address these issues effectively.

The Infinite Recyclability of Steel

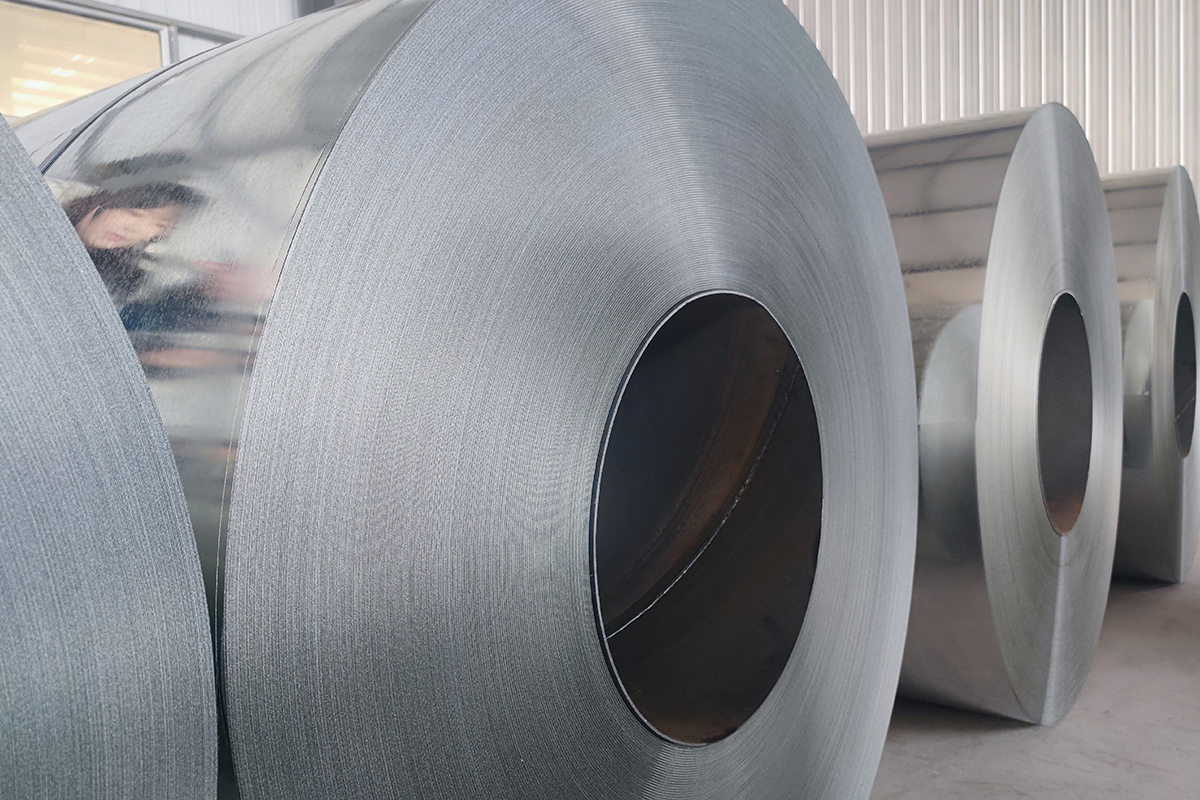

Steel is one of the most widely used materials globally, found in buildings, bridges, cars, and household appliances. But what happens when these products reach the end of their life cycle? Unlike other materials, steel’s journey doesn’t end there—it is 100% and infinitely recyclable without losing quality. End-of-life steel products are melted and reused to create new steel, forming a perfect loop of sustainability.

Steel scrap is primarily sourced from two categories:

- Prompt Scrap: Residuals from industrial manufacturing processes, such as appliance or automobile production. This type of scrap is valuable due to its high purity and concentrated volumes.

- End-of-Life Scrap: Products like household goods and dismantled structures that have reached the end of their use. Collecting and transporting this type of scrap involves challenges such as contamination and diverse origins.

Challenges in Scrap Processing

Sorting: Scrap must be carefully separated by type and quality, matching its alloy composition to the desired steel grade. The presence of unwanted elements, such as copper, makes this process complex and requires advanced sorting technologies.

Shredding and Melting: After sorting, large scrap pieces are shredded for easier transport and processing. They are then melted in furnaces, often electric arc furnaces (EAFs), which can operate with 100% scrap material, significantly reducing energy consumption and CO2 emissions compared to traditional blast furnaces.

The Future of Steel Scrap Recycling

Currently, around 650 Mt of end-of-life scrap is recycled annually, avoiding approximately 975 Mt of CO2 emissions and reducing reliance on natural resources like iron ore and coal. However, scrap availability is limited compared to global steel demand, as steel products often have lifespans of several decades. By 2050, the global supply of scrap is projected to increase to 900 Mt per year, but this will still fall short of the growing demand for steel.

Advancements in recycling technologies and processes will be essential to overcoming these challenges. Efforts to address alloy compatibility and improve sorting and refining methods will be key to maximizing the potential of steel scrap and achieving a more sustainable steel industry.