Cleanroom panels are essential for maintaining high standards of cleanliness and safety in various industries such as pharmaceuticals, electronics, food production, and healthcare. These panels are designed to meet the stringent requirements of clean environments by providing fire resistance, thermal insulation, soundproofing, and static control. Based on different needs, there are various types of cleanroom panels, each offering unique features and benefits.

- Flame Retardant Paper Honeycomb Cleanroom Panel

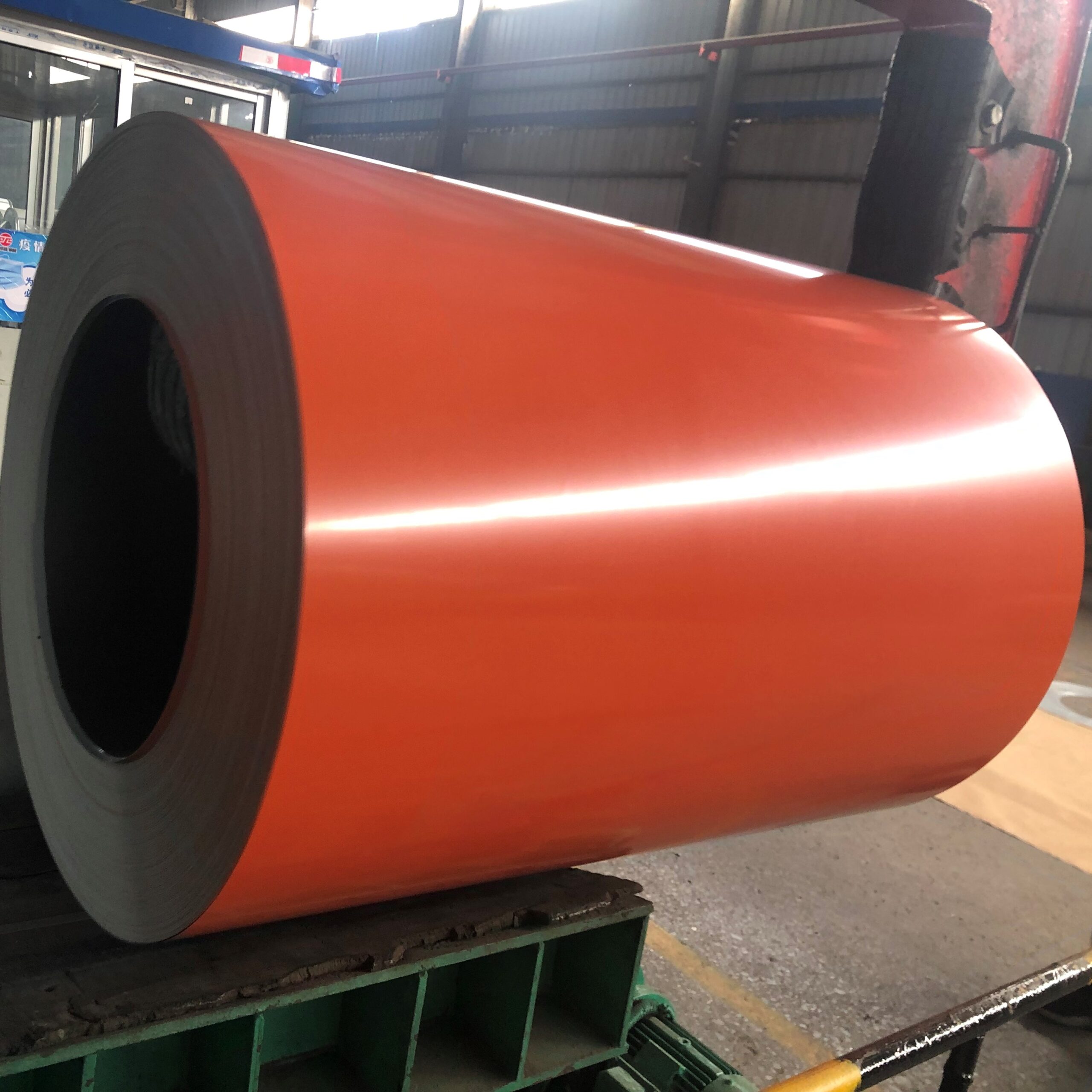

This panel features a core made of flame-retardant paper honeycomb, with surface panels typically made from color-coated steel or stainless steel.

Key Features:- Fire resistance of Class B1 (carbonizes but does not burn).

- High strength and rigidity, providing strong load-bearing capacity.

- Excellent insulation and soundproofing properties, with no toxic components.

- Rock Wool Cleanroom Panel

Rock wool panels have a “sandwich” structure, with color-coated steel as the outer layer and rock wool as the inner core, bonded with a special adhesive. These panels are known for their strong fire resistance.

Key Features:- Superior fire protection capabilities.

- Reinforced edges and strengthened surface for enhanced flatness and strength.

- Glass Magnesium Grid Cleanroom Panel

These panels feature a core made of glass magnesium grid and are coated with steel plates on both sides, with a cold-rolled frame around the edges. They are commonly used for ceilings, walls, and partitions in cleanrooms.

Key Features:- Aesthetic appearance with smooth surfaces.

- Good insulation, soundproofing, fire resistance, and seismic resistance.

- Can be customized with special core materials like steel-faced rock wool, aluminum honeycomb, or gypsum boards.

- High-Efficiency Anti-Static Cleanroom Panel

As the need for dust and static control grows in the cleanroom industry, this type of panel has been developed to reduce the risk of static electricity, which can damage sensitive electronic components and trigger fires.

Key Features:- Enhanced anti-static and dust-proof capabilities.

- Helps prevent the accumulation of dust and pathogens, ensuring a cleaner environment.

- Anti-Static Cleanroom Panel

These panels are coated with a special conductive paint, providing a surface resistance range of 10^7 to 10^9 ohms. This helps in the release of static electricity and reduces dust adhesion.

Key Features:- Anti-static, durable, and resistant to wear and contamination.

- Special enamel antibacterial agents are used for added long-term hygiene protection.

- Aluminum Honeycomb Manual Cleanroom Panel

With an aluminum honeycomb core, these panels are often used for high-performance cleanrooms. The core can be made of inorganic materials, gypsum, or aluminum honeycomb, with color-coated steel or stainless steel surfaces.

Key Features:- Fire resistance rating of Class A.

- Soundproof, insulating, and durable, meeting national standards for fire safety.

- Paper Honeycomb Manual Cleanroom Panel

Similar to the aluminum honeycomb version, these panels feature a paper honeycomb core, providing a lightweight solution for cleanroom applications.

Key Features:- Strong structural integrity due to the combination of steel surfaces and honeycomb core.

- Ideal for ceilings, walls, and partitions in industrial settings such as warehouses and cold storage.

Each of these cleanroom panels serves a unique purpose, depending on the specific requirements of the cleanroom environment. Whether it’s for fire safety, anti-static properties, or high insulation, selecting the right type of cleanroom panel ensures optimal performance and safety in highly regulated industries.