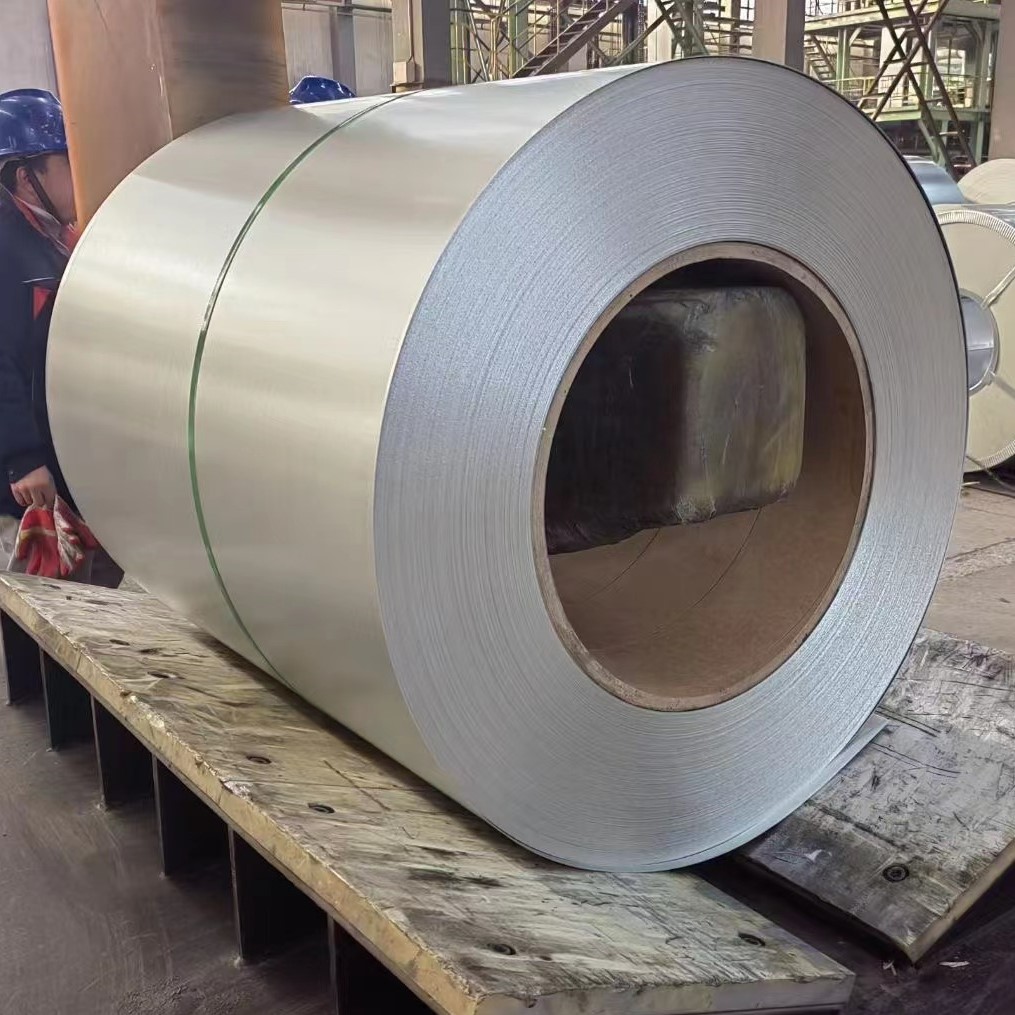

With the continuous advancement of the automotive industry and technological progress, the demand for superior material performance has steadily increased. Galvanized steel, known for its excellent corrosion resistance, high strength, and superior formability, has found broad applications in automotive manufacturing. Its usage spans various aspects of vehicle production, contributing significantly to improving durability, efficiency, and overall performance in the automotive industry.

1. Reinforcement and Protection of Vehicle Body Structure

Galvanized steel is a vital component in reinforcing and protecting the body structure of automobiles. It is commonly used in key parts such as car doors, hoods, roofs, and underbody panels. The primary advantage of using galvanized steel in these areas is its ability to provide essential structural strength while the zinc coating effectively prevents corrosion from environmental factors like moisture, chemicals, and atmospheric exposure. This corrosion resistance ensures that the vehicle body maintains its integrity over time, reducing repair and replacement costs due to rust damage and extending the vehicle’s lifespan.

2. Aesthetic Appeal and Durability of Interior Components

Beyond the vehicle body, galvanized steel is also utilized in the production of various interior components. Parts such as dashboards, door panels, and seat frames often use galvanized steel as the base material. This application ensures that the interior components have a visually appealing appearance and a smooth touch. Furthermore, galvanized steel’s high formability and resistance to corrosion guarantee that these parts remain durable and stable over the long term, even under frequent use.

3. Lightweight and Fuel Efficiency in Automotive Parts

As the automotive industry accelerates its shift toward lightweight vehicles, galvanized steel plays an important role in reducing the weight of vehicle components. By using high-strength galvanized steel, manufacturers can maintain the necessary component strength while reducing weight, leading to improvements in fuel efficiency and reduced emissions. Parts such as chassis and suspension systems benefit from galvanized steel’s ability to provide strength while contributing to the overall reduction of the vehicle’s weight, enhancing both its performance and environmental impact.

4. Support for the Development of Electric Vehicles

The role of galvanized steel is equally significant in the development of electric vehicles (EVs). Electric vehicles demand materials with enhanced properties, such as lighter weight, higher strength, and superior corrosion resistance, to support the complexity of electrical systems and battery packs. Galvanized steel meets these needs and has become an essential material in the manufacture of electric vehicle components, including the body, chassis, and battery packs. This contribution has been crucial in the rapid development and expansion of the electric vehicle market.

5. Technological Innovations and Future Outlook

As the automotive industry continues to evolve, the production technology and applications of galvanized steel are constantly improving. Advances in galvanizing processes and formulations are further enhancing the material’s corrosion resistance and forming capabilities. Additionally, with the emergence of new automotive sectors such as electric and connected vehicles, the scope of galvanized steel applications is expanding. The continued progress in material science and market growth will ensure that galvanized steel remains a vital material in the automotive sector, offering new possibilities and improving overall vehicle performance.

Conclusion

In summary, galvanized steel has become an indispensable material in the automotive industry. Its applications are widespread, from vehicle body structures to interior components and lightweight parts, and it plays a crucial role in the development of electric vehicles. With its unique combination of strength, corrosion resistance, and formability, galvanized steel is poised to remain a key material in the automotive industry. As technological innovations continue, the future of galvanized steel in automotive applications looks even more promising.