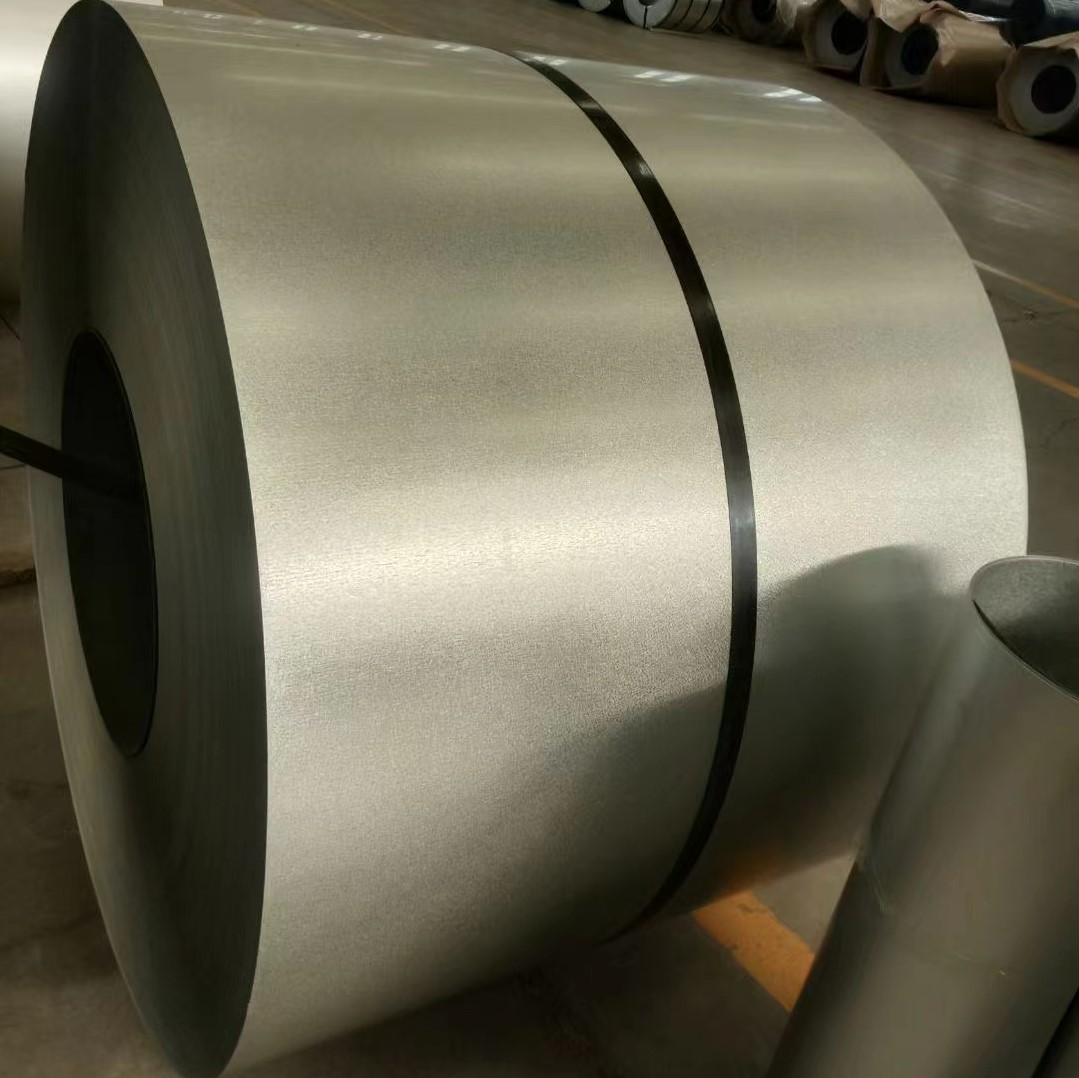

Galvalume steel, a versatile metal sheet combining the excellent properties of aluminum and zinc, has widespread applications in industries such as construction, automotive, and home appliances. To ensure the preservation of its quality and performance, it is crucial to adhere to proper guidelines during the transportation and storage processes. These precautions help maintain the integrity of the material and prevent damage or deterioration.

Transport Precautions

- Packaging Requirements

Before transportation, Galvalume steel should be properly packaged to prevent damage or contamination. Packaging materials must offer good shock absorption, waterproofing, and moisture resistance, such as wooden pallets, cardboard boxes, or plastic sheeting. The selection of packaging materials should consider the size, weight, and distance of transportation to ensure that the packaging can withstand the impacts and vibrations encountered during transit.

- Securing Methods

To ensure the stability of Galvalume steel during transportation, proper securing methods are essential. Common methods include the use of steel straps, ropes, and fasteners to secure the material tightly within the vehicle or container. The goal is to prevent displacement or tilting during transport, which could cause the steel sheets to collide and incur damage.

- Stacking Requirements

When stacking Galvalume steel, it is important to follow certain principles to avoid excessive pressure and deformation. Adequate spacing between sheets should be maintained to prevent mutual compression or friction. The stacking height should be controlled within reasonable limits to prevent excessive pressure on the sheets at the bottom. Additionally, the stacking area should be stable to avoid shifting or tilting during transport.

- Temperature and Humidity Control

Galvalume steel is sensitive to changes in temperature and humidity, so controlling these factors during transportation is crucial. This is especially important for long-distance or international shipments, where the material might pass through different climate zones. It is advisable to use containers or vehicles equipped with temperature and humidity control systems. Additionally, the temperature and humidity of the shipping container should be checked before loading to ensure it falls within an appropriate range.

- Avoiding Contamination

During transportation, it is essential to prevent Galvalume steel from coming into contact with contaminants that could affect its surface. Special care should be taken during loading and unloading to avoid exposure to dirt, oil, or other pollutants. Moreover, shipping should be avoided under harsh weather conditions such as rain or strong winds, which could lead to contamination or physical damage.

Storage Precautions

- Storage Environment

Galvalume steel should be stored in a dry, well-ventilated, and dust-free environment. The temperature should be controlled between 0–30°C, avoiding high temperatures or the presence of fire sources. The humidity should not exceed 75%, and the storage facility should maintain adequate ventilation, ensuring that the oxygen content is above 18% to prevent corrosion.

- Classification and Labeling

During storage, Galvalume steel should be organized based on specifications, material types, and measurements. Similar products should be clearly separated. Proper packaging and labeling should be used to avoid confusion and ensure the safe handling of the materials, preventing loss or misidentification.

- Protection Measures

To protect Galvalume steel during storage, it is important to prevent exposure to water droplets, dust, or other contaminants. Measures such as moisture prevention and dust control should be implemented to keep the surface clean and aesthetically appealing. For long-term storage, applying rust-resistant oils or agents to the surface can help extend the material’s lifespan and maintain its quality.

Conclusion

In conclusion, the transportation and storage of Galvalume steel require strict adherence to specific precautions to maintain its quality and performance. By employing appropriate packaging, securing methods, proper stacking techniques, temperature and humidity control, and avoiding contamination, the safety of the material during these processes can be ensured. These steps are vital in protecting Galvalume steel and preserving its valuable properties throughout the supply chain.